-

How EPP foam can be beneficial for HVAC structure casing

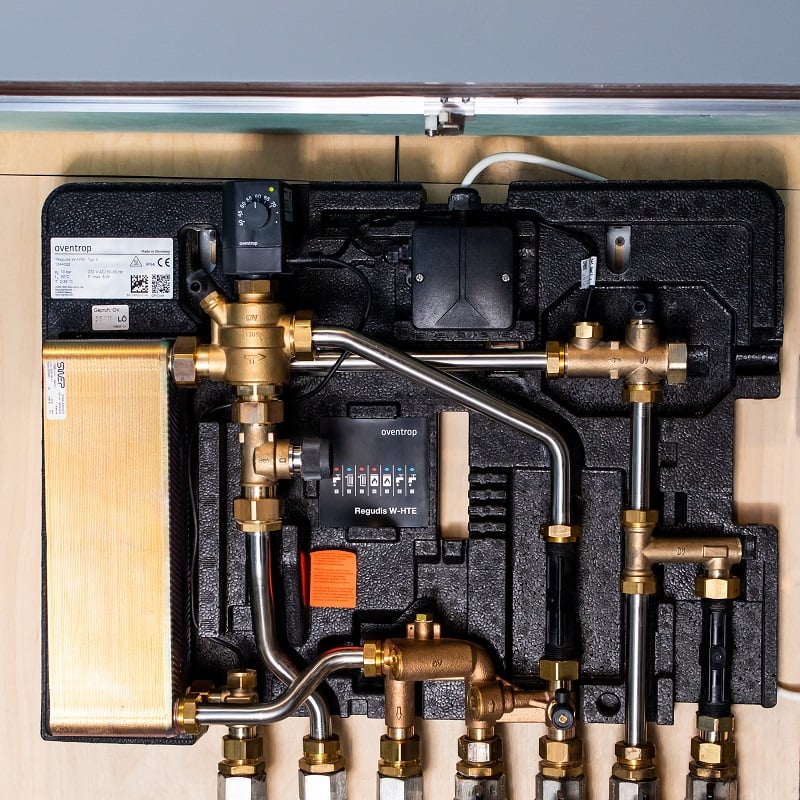

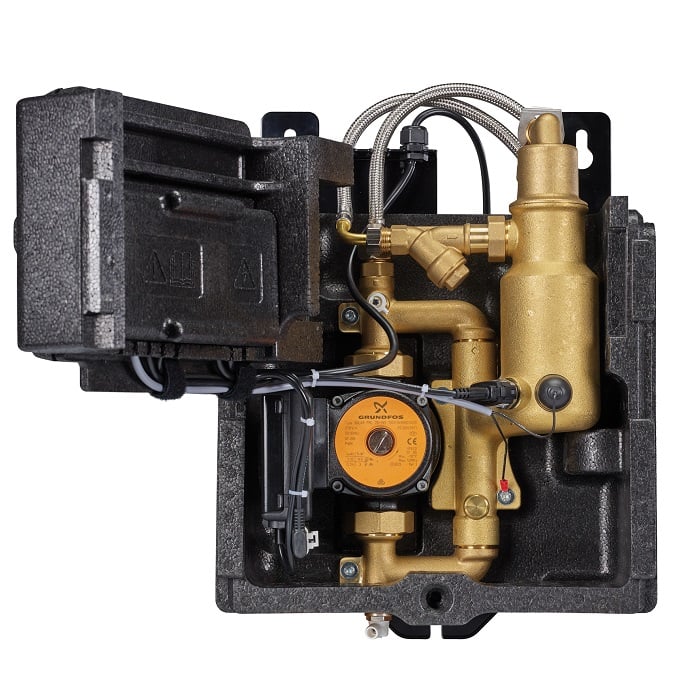

EPP is an excellent material choice for HVAC structural parts because it can be molded into complex shapes without losing its resiliency.The design flexibility of EPP enables key system components such as pumps, boilers, valves, heat-exchangers and control mechanisms to be universally housed in EPP to improve their insulation.

넶0 2024-04-01 -

Transport and insulation made easy with EPP foam boxes

EPP foam cooler and heat insulation boxes are increasingly popular for various cooling and storage needs due to their excellent insulation properties, durability, and lightweight construction.

넶1 2024-04-01 -

EPP foam insulation boxes

EPP insulation boxes have become indispensable companions for many families during outdoor activities such as picnics, camping, and travel. Whether it's cold drinks, fruits, or cooked food, as long as they are placed in EPP insulation boxes, they can be kept fresh and at the desired temperature, allowing you to enjoy delicious food even outdoors.

넶5 2024-03-22 -

EPP foam, Expanded Polypropylene, is a popular material for various applications due to its lightweight, durable, and buoyant properties.

For surfboards and efoils, EPP foam can be an excellent choice due to its buoyancy and impact resistance.

넶10 2024-03-21 -

Here's how EPP foam is utilized in wine packaging:

Expanded Polypropylene (EPP) foam is commonly used in wine packaging applications due to its excellent cushioning and protective properties.

넶10 2024-02-27 -

Reasons for choosing EPP foam material for packaging

EPP foam material, as a new environmentally friendly packaging material, has excellent buffering performance, soft touch, environmental protection and recyclable, wide range of applications, good heat insulation performance, strong durability and other characteristics, so it is widely used in the field of packaging.

넶30 2023-11-27 -

EPP insulation cooler box is your ideal choice!

This is our EPP insulation box, a thermal insulation equipment made of advanced EPP materials. Whether it is in catering, medical, industrial and other occasions that need insulation, or in picnics, outdoor activities and other mobile occasions, EPP insulation cooler box is your ideal choice!

넶16 2023-11-27 -

What are Helmets Made of?

Learn about the differences in materials used to construct a helmet.

Expanded Polypropylene (EPP) foam is often chosen for helmet liners due to its unique set of characteristics that make it well-suited for impact protection and comfort. Here are some reasons why EPP foam is commonly used in helmet liners:넶32 2023-11-27 -

Why choose ETPU foam material for pet chew toys

ETPU materials provide a unique combination of durability, safety, and comfort that make them the best choice for pet toys. Whether you’re looking for a chew toy, a ball, or a flying disc, consider investing in an ETPU pet toy for hours of fun-filled playtime with your furry friend.

넶33 2023-08-31 -

EPP foam shockpad underlayment for Artificial Grass football playground

Using EPP foam drainage shock pad in sports artificial grass football pitch as underlay not only benefits the environment but also the sports industry as a whole. Its shock-absorbing properties can help reduce the risk of injury to athletes, while its lightweight and durable nature makes it an ideal material for sports that needs to withstand intense use.

넶39 2023-08-28 -

EPP foam helmet liner or EPS foam helmet liner for Helmet?

Foam is used for energy management in most helmets. There are many types, but EPS is still the choice for most bike helmets. The ideal foam would be stiffer in hard impacts, softer in lesser impacts, light, cheap, reliable to manufacture and easy to ventilate.

넶52 2023-08-27 -

Benefits of using expanded foams for packaging (including cost and weight reduction)

EPS, and especially EPP, are excellent protective packaging materials due to their mechanical strength and shock and vibration damping capacity. This protects the goods from careless handling, bumps in the road or an unfortunate fall.

넶60 2023-08-21 -

How EPP foam can be beneficial for HVAC structure casing

Using Expanded Polypropylene (EPP) foam for HVAC (Heating, Ventilation, and Air Conditioning) structure casing offers several advantages in terms of insulation, durability, and customization.

Here's how EPP foam can be beneficial for HVAC structure casing:

1. **Insulation Properties**: EPP foam has excellent thermal insulation properties, helping to prevent heat transfer between the HVAC components and the surrounding environment. By minimizing heat loss or gain, EPP foam casing helps improve energy efficiency and maintain optimal operating conditions for HVAC systems.

2. **Lightweight Construction**: EPP foam is lightweight yet structurally robust, making it easy to handle and install as casing for HVAC components. Its lightweight nature reduces the overall weight of the HVAC system, which can be beneficial for transportation, installation, and structural support requirements.

3. **Impact Resistance**: EPP foam is known for its impact resistance, providing protection to HVAC components against accidental impacts or vibrations during operation or maintenance activities. This helps to prolong the lifespan of HVAC equipment and reduce the risk of damage.

4. **Customizable Design**: EPP foam can be easily molded into various shapes and sizes, allowing for customized designs that fit specific HVAC components and configurations. This flexibility enables precise fitting and integration of the casing with different HVAC structures, including air handlers, ductwork, and piping.

5. **Noise Reduction**: EPP foam has sound-absorbing properties, which can help reduce noise levels generated by HVAC systems. By enclosing HVAC components with EPP foam casing, noise transmission can be minimized, improving indoor comfort and reducing disturbances in residential, commercial, or industrial settings.

6. **Moisture Resistance**: EPP foam is inherently resistant to moisture, preventing water absorption and mold growth. This feature is particularly advantageous for HVAC casing applications where exposure to humidity or moisture is a concern, ensuring long-term durability and performance.

7. **Chemical Resistance**: EPP foam exhibits resistance to a wide range of chemicals, including oils, solvents, and cleaning agents commonly used in HVAC systems. This chemical resistance helps maintain the integrity of the casing and protects HVAC components from corrosive substances.

8. **Recyclability**: EPP foam is recyclable, contributing to sustainability initiatives in the HVAC industry by reducing waste and promoting the use of eco-friendly materials. At the end of its service life, EPP foam casing can be recycled or reused, minimizing environmental impact.

Overall, EPP foam offers a versatile and cost-effective solution for HVAC structure casing, providing insulation, durability, customization, and other beneficial properties that enhance the performance and longevity of HVAC systems.

We do customized shape molded EPP foam structural parts for HVAC heater pump, boiler, valve, airfilter, etc, if you have such enquiry, you can email us at Email